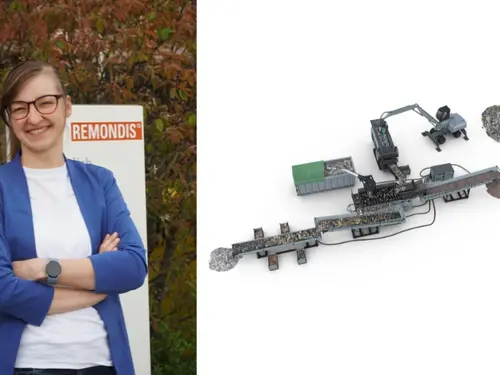

Construction waste or Contaminated demolition waste contains valuable raw materials such as concrete, wood and metals, the recovery of which represents a global challenge. With our Mobile Modular Processing Concept (MMPC), you can solve this problem efficiently: modular in design, flexible in use and economically attractive, the MMPC offers customised solutions for the processing of contaminated material flows - sustainable and future-proof.

THE FUTURE IS MOBILE-MODULAR.

Our experts smartly combine robust Doppstadt machines and proven add-ons to create a mobile-modular system. You can use all machines flexibly in different fractions. You can react quickly to changing conditions by recombining the system components. This means you are ideally equipped for the economical and legally compliant processing of your mixed demolition waste - no matter what challenges await you in the future.

USE OUR IDEAS TO YOUR ADVANTAGE.

- By mobile-modular processing concepts, we mean the combination of mobile Doppstadt machines according to the modular principle. Intelligently combined, they can be used in many applications.

AN INVESTMENT THAT PAYS OFF.

- Future-proof solutions with Doppstadt's mobile modular processing concept MMPC

- Flexible utilisation of the machines in different fractions

- Quick response to changing conditions thanks to new combinations

- Low investment volume

- Reduction of disposal costs by approx. 30-40 %

USE OUR IDEAS TO YOUR ADVANTAGE.

By mobile-modular processing concepts, we mean the combination of mobile Doppstadt machines according to the modular principle. Intelligently combined, they can be used in many applications. As the operator, you have a wide range of options to customise the system precisely to your material and volume flows. If these change, you can react quickly. All machines can be flexibly moved and repositioned.

Six steps that will take you further.

The presented processing concept is individually adapted to the respective material requirements of the customer. Depending on the input, process steps are added to meet customer needs and ensure the fastest possible ROI.

Pre-shredding and digestion of the material using Methor for dosed material feed for the subsequent processing steps.

Separation of the Fe component via overband magnet on the methor.

Separation of the material into coarse and fine grain using the SELECTOR 400. Uniform and spreading of the material flow for air separation.

Steplessly adjustable air separator for discharging 2D light fractions.

The fines (sand) are efficiently and reliably separated from the rest of the material flow using a Doppstadt screening machine.

The HDS-M separates materials according to their density using a float-sink process.

In a water bath, light materials float to the top while heavy components sink. This effect is enhanced by an upward flow, which enables precise separation.